|

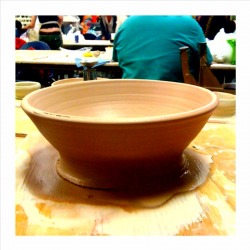

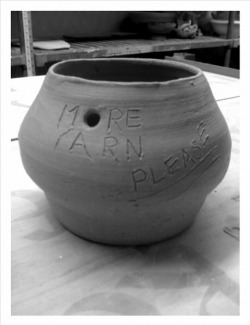

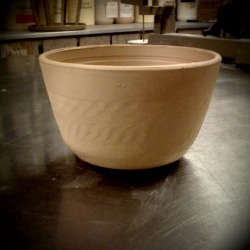

I think the wheel is becoming my new friend - I made 3 bowls last night - 2 of them turned out pretty well (this is one of those) and the third one is OK enough to keep going forward with, but it was a little more wonky... I learned that the base of the bowl should be about 1/2" thick and the sides about 1/4" - I have a tendency to make the bottom too thin - but that makes it almost impossible to trim when it's leather hard... This is the "first" pot I threw on day 1 of the class this semester... it's not perfect that's for sure - and too small for a "real" yarn bowl (it'd work good for sock yarn I guess) and the walls were too thin for me to cut the notch to the yarn feed hole... but it's still worth working on... someone may want it :) - I plan on making bigger yarn bowls once I know what I'm doing.. I like how this one turned out - you can't see the foot of the bowl but it's there - tucked nice and deep beneath the bowl... we learned the basics of trimming and what makes a good bowl - following the interior and exterior curves so they match each other is important... and it takes practice. I'm happy at this point getting what I set out to do... that's not happening yet but the series of "happy accidents" has been fun! I got a little brave with the trimmer on this one... the foot turned out good but as I was carving the lines up the bowl's sides, I got VERY close to cutting the piece in half! You can see the mark pushing through on the inside of the pot... I don't know if it'll look good after it's first firing, but it's on the shelf, waiting to be loaded and fired! |

Archives

July 2023

Categories

All

|

ExploreFor Fun

|

Support |

Connect |

© 2006-2023 Kyle William. All Rights Reserved.

RSS Feed

RSS Feed